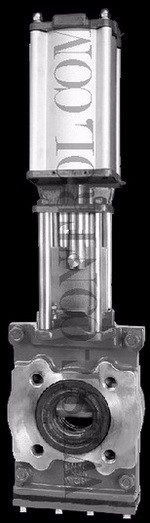

Valve Type: Slurry knife gate valve

Valve Nominal Size: DN50 through DN600; 2 inch through 24 inch

Pressure Rating: PN10

Body Style: Wafer knife gate

Temperature Range: NBR seat from -20°C to 120 °C; EPDM seat from -20°C to 100 °C;

Natural rubber seat from -20°C to 70 °C; Viton seat from -20°C to 200 °C

Body Material: Carbon steel, Stainless steel

Stem: Stainless steel

Gate Material: Stainless steel with hard chrome plated

Seat Material: NBR, EPDM, Natural rubber, Viton

Seat Leakage: Zero leakage

Actuator: Pneumatic Cylinder actuator; Manual operator

Description & Features

CV6300 slurry knife gate valves are soft sealing linear shut off valves that are light weight with compact construction and convenient to install and use. Valves are full port in design to realize the characteristic of small flow resistance. When the gate is open, it will achieve direct current between valve and pipeline. Valves are available as manual with hand-wheel, or can be automated with actuator for remote operation. The cone-shape design of the gate provides strong cutting force. The die-casting rubber seat which can realize bi-directional sealing. The biggest characteristic of valves is that when they are fully open, the medium will not come into the valve chest, which can prevent the valve chest from setting pulp during the valve running online, then reducing maintenance cost.

Arc shape gate provides strong cutting force, each gate is precision ground and hard chrome plated as a standard. It provides superior abrasion and corrosion resistance.

Packing gland and packing are internally located, which realizes stable sealing and easy online maintenance.

Two piece body, light weight and compact. The body is designed without any cavities, so there is no place for solids to accumulate, with the design, even with high solids content in the slurry, the valve will not jam.

Resilient and abrasion resistant rubber seat are die cast in a unique rubber mould, and have a metal support ring to extend the life of the valves. Seat material options are NBR, EPDM and Naturel Rubber.

The bottom discharge cover can easily be removed for routine cleaning. Customer can also outfit the valve with their own purge system.