Valve Type: Labyrinth cage guided velocity control valve

Valve Nominal Size: DN25 through DN500; 1 inch through 20 inch

Pressure Rating: PN16, 40, 100, 160, 250, 400; ANSI Class 150, 300, 600, 900, 1500, 2500

Body Style: Cage guided globe or angle

Trim Type: Balanced plug, multi-stage labyrinth cage

Flow Direction: Flow over the plug; Flow under the plug

Flow Characteristic: Linear or special designed

Rangeability: 50:1 to 20:1

Temperature Range: From -196°C to 538 °C

Seat Leakage: Metal seat ANSI IV or V; Optional soft seat ANSI VI

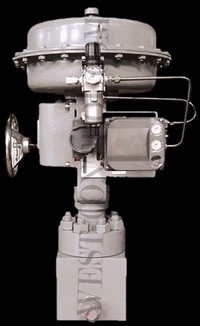

Actuator: Pneumatic diaphragm actuator; Pneumatic cylinder actuator;

Electric actuator; Hand-wheel manual for option

Description & Features

CV2900 Labyrinth trim control valve prevents the damaging effects of noise and erosion typically associated with severe service applications, as high pressure drop conditions and the potential for fluid to develop high velocities when passing through the control element. In some cases, process temperature contributes to severe service conditions.

Multi stage stacked disk trim designed with constant area rations that provide a torturous path controlled pressure drop at each stage. Use of this design totally precludes the high velocity in compressible flow that creates noise or the critical pressure drops in flow that creates cavitation.

Prevent cavitation, zero stem leakage, have safe and long life.

Trim permits quick disassembly and easy maintenance, reliability and reduced maintenance costs by preventing cavitation, erosion, noise, and vibration.

Wear resistance and prevent trim sticking or galling by advanced design and technology, high grade material and fine pairing.

Noise reduction more effectively than competitors’ similar product.