The industry choice for a simple, reliable, tough globe valve. Handles a wide selection of process control applications for flow, pressure, and temperature, including corrosive fluids, cryogenics, steam, water, gases, multiphase, high temperatures, erosion, and high pressure drops.

Description & Features

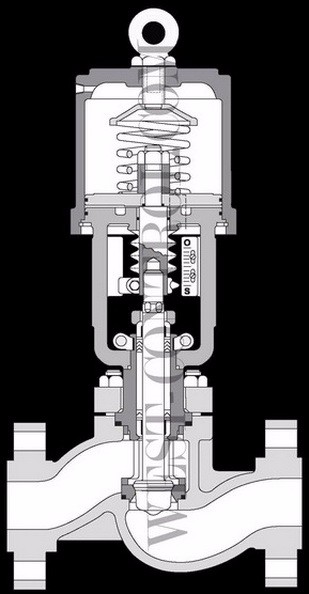

Compact, robust design: minimum mounting space required, low weight.

Self-centering seat: reproducible seat tightness (metal seat: leakage class ANSI V/VI), quickly and easily to be disassembled and maintenance.

Integrated forged heavy-duty stem with plug: as large diameter stem is 3~5 times than traditional diaphragm control valve’s, for blowout proof and avoid bending or crack even applied for condition along with high temperature & high pressure & high differential pressure.

Double top stem guided design: guide completely avoids contact between the plug and seat retainer for eliminate trim sticking or galling associated with cage guided to guarantee long term and high performance steady service.

Twin packing set: ensure perfect packing sealing.

For a given valve size with several CV values while using the same bonnet and body.

Clamped-in seat ring and top entry trim permits easy, quick maintenance.

Chosen flow direction is flow to open, valve as single seat control valve, chosen flow to close direction valve as caged guided control valve.

Tight shut-off combined by spring, the supply air pressure, and the fluid pressure itself.

Anti-cavitation and noise, velocity control trim options.

Standard (pressure unbalanced), pressure balanced, high pressure, high temperature, cryogenic, bellows seal, jacket, anti-corrosion, diaphragm actuated control valve, angle control valve, electric control valve options.

Standard actuator is double acting spring cylinder actuator: available up to 10bar air supply, Light weight, stiff, high-thrust overcomes high pressures, quick travel as fast move to required position only if air failed.