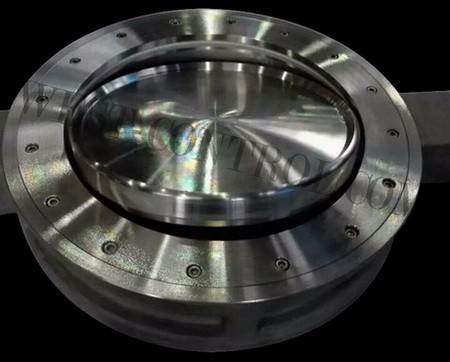

Valve Type: High performance butterfly valve

Valve Nominal Size: DN50 through DN1500; 2 inch through 60 inch

Pressure Rating: PN16, 40; ANSI Class 150, 300

Body Style: Wafer, Lugged double offset butterfly

Flow Direction: Bidirectional; Unidirectional

Flow Characteristic: Nearly equal percentage EQ%

Temperature Range: From -40°C to 260 °C

Body & Disc Material: Carbon steel, Alloy steel, Stainless steel, Titanium, Hastelloy, Super duplex, Monel

Stem Material: 17-4PH S/S, Monel, Inconel

Seat Material: PTFE, RTFE, PEEK, PPL

Seat Leakage: ANSI VI or zero leakage

Actuator: Pneumatic rack and pinion actuator; Pneumatic scotch yoke actuator;

Rotary Diaphragm Actuator; Electric actuator;

Hand-wheel manual for option; Manual operator

Description & Features

CV3100 high performance butterfly valve is a double offset has been designed into the disk to lift it out of the seat immediately upon opening actuation, this avoids wear on the seat and disk, by reducing leakage and parts replacement. It also improves throttling by eliminating friction.

Long life & High performance

Testing and using indicate that a combination of components yields significantly longer life than a standard configuration valve.

Actual cycle performance is subject to media, pressure and temperature conditions. Applications such as oxygen, nitrogen, hydrogen, water and clean media are ideally suited for option.

Double direction sealing

When pressure is on the insert side, pressure is applied under the seat lip, this further amplifies the sealing force between the disc and the seat.

When pressure is on the non-insert side, the disc moves into the seat, Due to the spherical profile of the disc, the more the disc moves into the seat, the tighter the shut-off. Excessive movement of the seat is limited by the flexible lip which contacts the bottom of the groove in the insert ring.

On-off and Control Applications

Superior control characteristics, wide rangeability, Inherent flow characteristic is modified equal percentage and tight shut off even in control applications.

Double offset (eccentric) design.

Contact cover design.

Zero leakage design.

Welded disc pins.

Integrally cast disc stop.

Bottom stem using RTFE washer.

Blow-Out Proof Stem.

Bi-Directional Service.

Inserts screws, to facilitate the replacement of the seat.

Available in different seat.