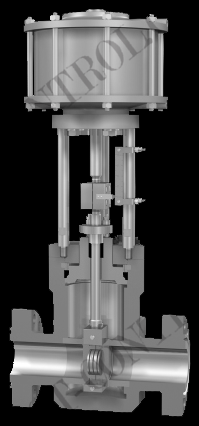

Valve Type: Double disc parallel slide gate valve

Valve Nominal Size: DN15 through DN1200; 0.5 inch through 48 inch

Pressure Rating: PN16 through 420; ANSI Class 150 through 2500

Body Style: Double flanged or welded parallel slide gate

Bonnet Style: Bolted or pressure seal

Temperature Range: From -196°C to + 600 °C

Flow Characteristic: Quick open, Linear or EQ%

Body & Bonnet Material: Carbon steel, Stainless steel, Alloy Steel

Stem Material: Stainless steel, Alloy Steel

Disc Material: Stainless steel, Alloy Steel

Wedge & Disc Follower Material: Stainless steel, Alloy Steel

Seat Material: Metal seat stainless steel with stellite overlay

Seat Leakage: ANSI VI or tight shut-off

Actuator: Pneumatic cylinder actuator; Electric actuator;

Hand-wheel manual for option; Manual operator

Description & Features

Parallel slide gate valves with spring-loaded double discs CV7200 are designed for more reliable fluid tightness and valve operation in flow control, widely used to various liquid or gaseous medium as crude oil, steam and water which required tight shut off or vent to atmospheric application, specially use in emergency isolation under high temperature and high pressure as hydrogenation unit.

Bolted bonnet or pressure sealed bonnet is option.

Spring loaded parallel sliding discs.

Hard faced Stellite or equivalent discs and seats.

Wide flat seats and wide seat diameter relatively.

Complete flow isolation in either direction.

Regulating with V or T-ported seat.

Available structure for the bypass piping.

Improved sealing assisted by line pressure, seals on position not torque.

Thermal Binding is associated with wedge gate valve, which occurs when wedge gate valve is closed at high temperature and is allowed to cool before attempting opening. Thermal binding cannot occur with a parallel slide gate valve.

Freedom from leakage independent of temperature or pressure changes.

Self-aligning fully supported discs.

Self-cleaning action between disc and seat.

Disassembly for repair easily and interchangeable parts.

Lower pressure drop characteristic than wedge gate valves.

Low operating torque, reduced actuator size when compared to wedge gate valve.

Low cost and in-line maintenance.

Low noise.